24th May 2021

At Conduce, we believe in the power of automation. From the nature of our work and the background of our team, we have seen first-hand how new technology has improved our lives. Systems and machines can take care of more and more tasks that we had to do ourselves in the past. With what appears to be lesser workload, we have time to focus on more critical tasks or new projects (warning: appearances can be deceiving!).

Just think of that last bill that you set up an automatic payment for, or that fancy fridge that checks food in stock and makes a shopping list for you. It is all pitched at saving you time. But this happens not only at home. Automation is everywhere! Especially in the aviation industry, where every second is precious, and pilots’ or engineers’ attention is a matter of life and death.

Since the 80s, scientists have proven that increased automation diminishes the likelihood of aircraft accidents and delays. For example, in 1996 Charles Billings proved ground proximity warning systems in transport aircraft significantly decreased terrain incidents. Likewise, Robert Ropelewski demonstrated that embedding automation in the cockpit as part of the manufacturing process of a B767 improved the crew’s performance. We won’t bore you with all the examples we found, but, as you see, the evidence is out there.

In the same trend, our eTechLog8 application offers plenty of automation possibilities to our customers. While implementing eTechLog8 as the aircraft technical logbook, we dedicate a great deal of time and effort to customise the solution in line with customer procedures and applicable regulations. This customisation extends from importing files or setting up statements to… You guessed it! Automating processes. On the eTechLog8 device, our customers mainly notice this automation in two ways:

1. The system pre-populates information for a specific field.

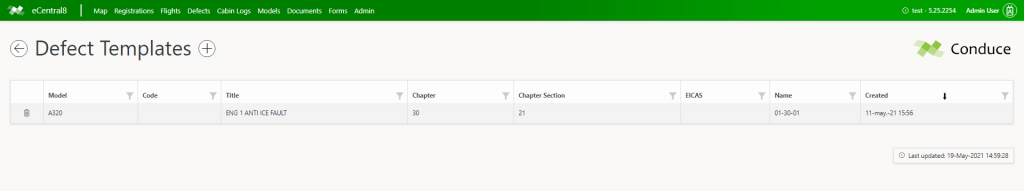

Defect templates are a great example of this. Some of our customers choose to add defect templates for standardising or simplifying the process of entering a defect. To make this happen, first we have to upload a list of defect templates to the eCentral8 website.

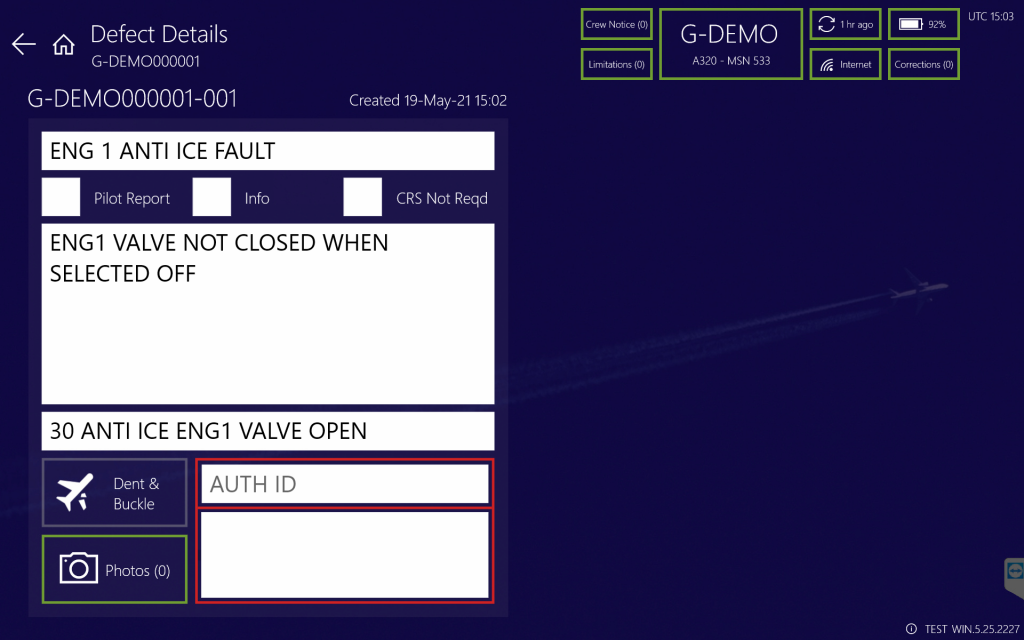

The defect templates are then displayed on the eTechLog8 device as a dropdown list n the defect description field. The users select the required template and then all the fields on the screen, excluding the signature box, are automatically populated:

We highly recommend using defect templates as it helps standardisation and speed. However, this is an example of where we trust the automation because a human being has curated and checked the defect templates list before uploading it.

We ensure a human has monitored and checked what the system will use automatically.

2. The system performs a function as a result of a specific user action.

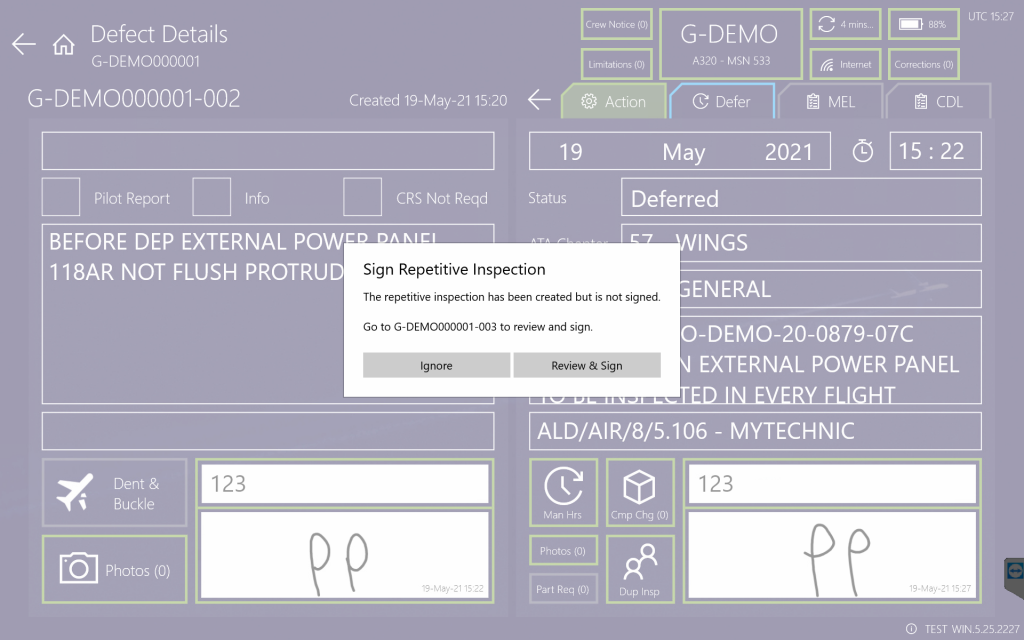

Our brand-new repetitive defect inspection feature is the best example of this type of automation. In fact, we implemented this feature after realising that many eTechLog8 users forgot to action and close the corresponding defect and defect action entries when recording repetitive inspections. With this automation, we nailed one of the ultimate goals of eTechLog8: to reduce human errors.

So how does it work? When eTechLog8 users mark a defect action for a repetitive inspection, the system automatically creates a secondary defect entry that falls under the scope of the original one. This first one is the grounds for the repetitive inspection:

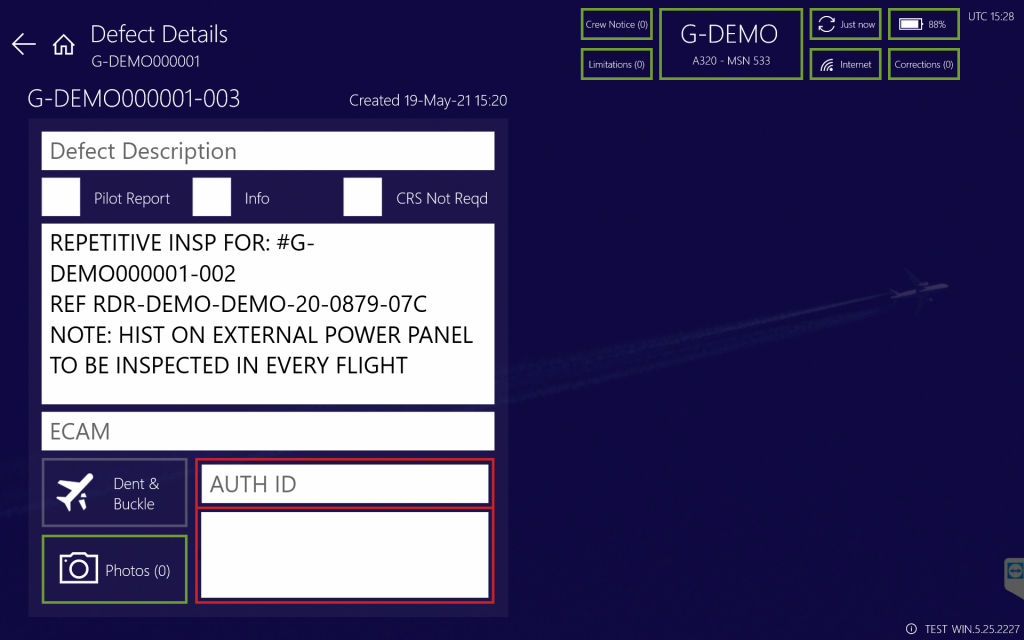

Then, the users have to review the pre-populated information and sign the automatically created record. This automated entry prevents the eTechLog8 users from forgetting to record a new defect while keeping the database accurate and updated.

Any automation must be carefully thought through.

Firstly, the signature box is never prepopulated. The user must sign the record that has been automatically created in both scenarios. Signing these records ensures it is clear who is legally liable for the record. The National Airworthiness Authorities who have approved eTechLog8 in the field have been clear that this is their hard line for automation – any more would sensibly be off-limits.

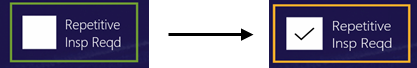

Secondly, a human action triggers the automation, which means it was an intentional eTechLog8 user decision to create a repetitive inspection entry. When the users decide to tap on the dedicated Repetitive Insp Reqd button, the system acknowledges this action by turning the button amber.

So in all our examples so far, automation has been carefully considered and we have ensured there is ultimately human oversight.

But sometimes we can all get a little overexcited about automation. We find ourselves being asked What if we prepopulate this field? What if we make this area non-mandatory? Well, in the words of the Spice Girls, too much of something is bad enough.

And there’s a good reason to be wary of too much automation. Extensive research has proven that too much automation has adverse effects because people lose attention or may not understand what is happening. Ultimately, the consequences of this can be devastating.

As Lisanne Bainbridge claimed, this is the irony of automation. As the system becomes more reliable and automated, the users disengage because they trust the system will do everything for them.

And maybe buying whatever your fridge told you to get is okay (if you want to eat the same thing every week!), but a pilot in autopilot mode is definitely not okay. For Conduce it’s imperative that we keep eTechLog8 users fully aware and in the loop.

So how do we achieve this? Reading up on Mica Endsley, an aviation automation guru, led us to believe that the eTechLog8 users need to really know whats happening to really figure out what to do. Or, as Mica would put it, users need to retain situational awareness. Otherwise you might end up in a situation like the one on the left there!

Ensure automation setup doesn’t put situational awareness at risk.

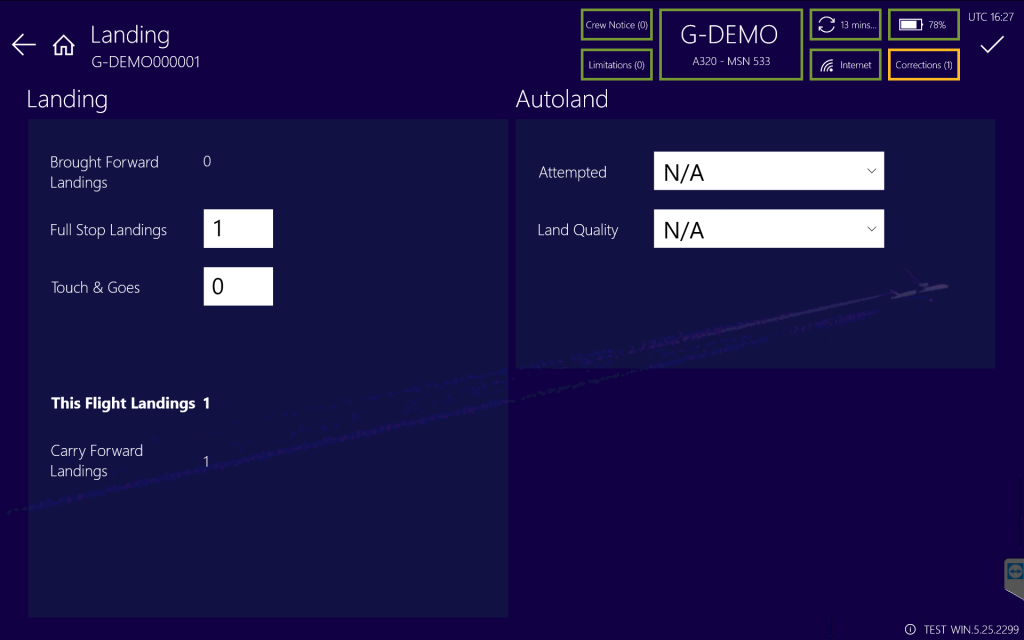

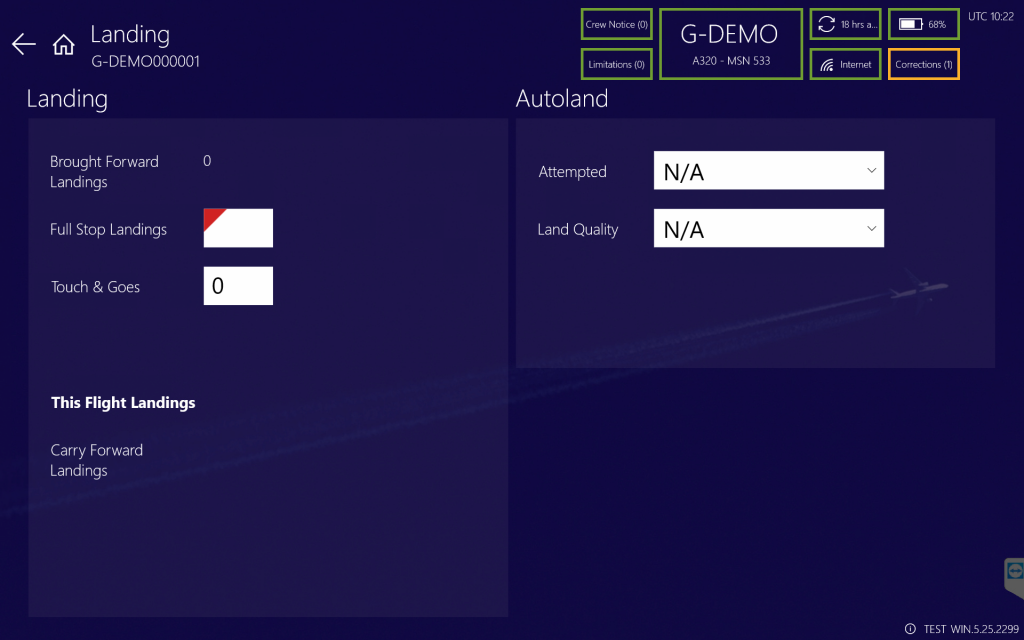

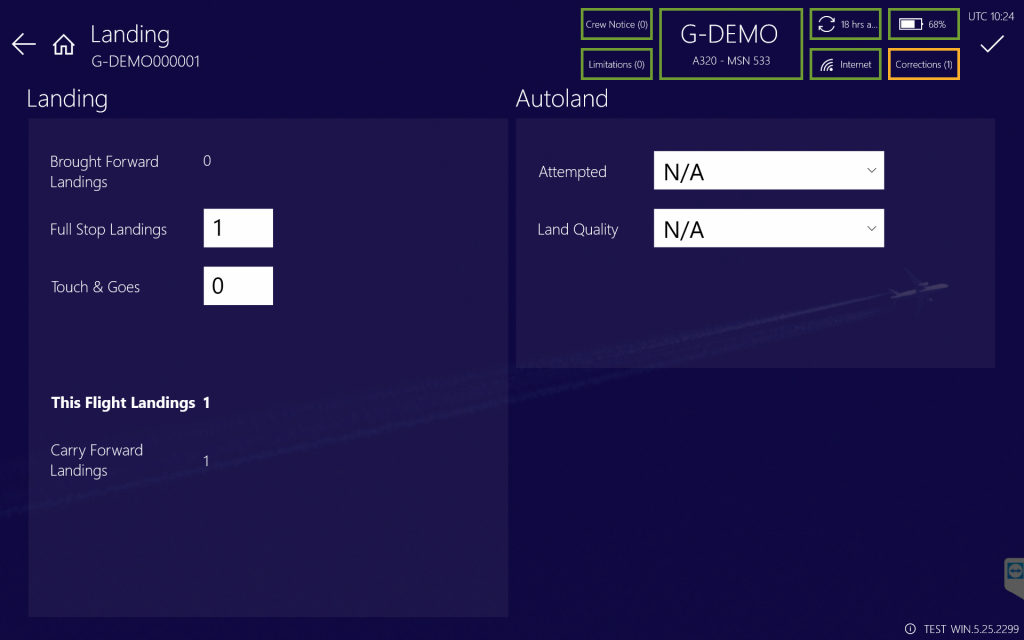

Here’s an example to illustrate the point. On eTechLog8, the Landing Data screen collects information about Full Stop Landings, Touch & Goes and Go Arounds, among others. This data is fundamental for tracking aircraft reliability and performance. We often get asked if we can pre-populate the Full Stop Landings with 1, and Touch & Goes and Go Arounds with a 0.

In fact, we can easily do this on eCentral8! But we are actively against this. Why? Because the moment we automate these fields with pre-populated data, the users will stop thinking about recording that data.

The Landing Data button frame will always be green, which means that no user action is necessary to proceed. When users see this, they become less likely to ensure they really know what is going on there. In a real-life test, we users did not regularly review the Landing screen to include the actual Full Stop Landings, Touch & Goes and Go Arounds values. The users over-relied on the system, as they were not forced to record or check the data.

Ultimately, some of the Touch & Go and Go Arounds that occured during the test were not recorded on the techlog pages (TLPs).

The automation setup (i.e., the pre-populating fields) reduced the users’ situational awareness. The users still manage to capture data from their environment. They knew that the aircraft had fully stopped, or did a Touch & Go, or had a Go Around. But they seemed to stop being vigilant about recording it in eTechLog8. In our test, the users did not fully comprehend that having one Touch & Go required them to intentionally change that 0 to 1.

Furthermore, as the users did not include this information, they were actually forgetting about the need to enter accurate data into the system as it will ultimately impact aircraft records.

We discovered that too much automation could actually cause errors, precisely the thing that automation is supposed to help us with!

But, as we said at the beginning, we still believe in automation. But only when it is fully thought through. And what we mean by thought through is that we automate processes not to reduce the users’ workload. Boom!

Yes, that’s right. We think that’s an old-fashioned approach to automation. Once again we’re backed up by the science; research shows that automation does not necessarily reduce workload. Automation simply shifts the focus or the quality of the workload so humans can concentrate on highly cognitive tasks or monitor previously manual processes.

We intentionally do not use automation to just lighten the workload of users. Instead we design automation in to keep users in control without feeling overloaded.

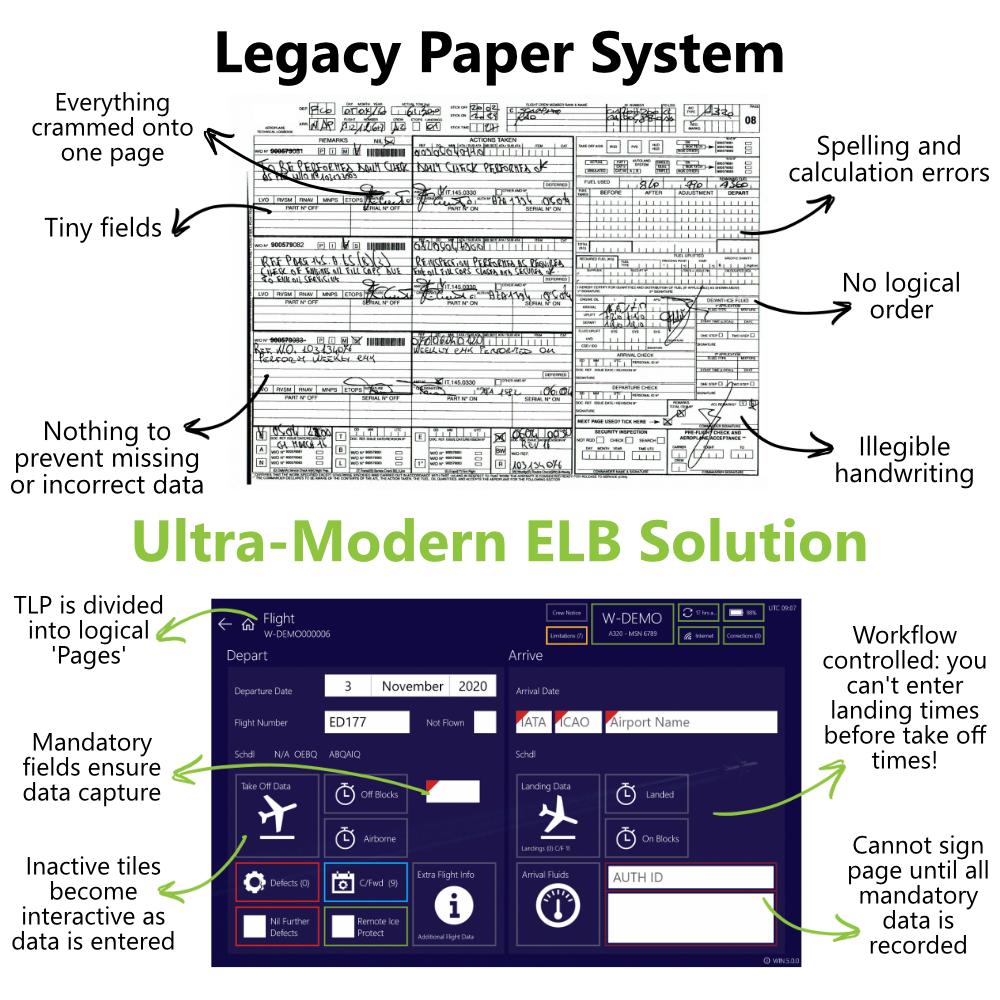

Another example will help here. We said earlier that automation is obvious in two ways on the eTechLog8 device. In reality we automated the entire Tech Log Page workflow.

When you begin filling our an eTechLog8 TLP, new fields, and buttons become active as you fill in the data. This is a kind of automation that prevents users from feeling overloaded; they only have to worry about one area at a time.

And we’re sure this is a hundred times better than the legacy paper process. Remember filling out a stack of paper, printed in a nano-size font (which you can’t even read without glasses), with a pen about to run out of ink, in rainy airport with the paper getting increasingly soaked?

Whereas eTechLog8 customers can use the colour code system to fill in the TLP quickly and easily, with fat finger friendly buttons. Red buttons and triangles indicate mandatory fields ensuring users know what they really need to be aware of, and what they really need to record.

So that’s why we think you should make your Full Stop Landings field mandatory, and not automate it.

However we have implemented some thought out automation here: the system will calculate the total number of landings for you, so you can say goodbye to adding it all up on your fingers and toes!

We’re going to leave you with one final example from the repetitive inspection feature.

The automatically-created secondary defect entry is shaded in red until the users review and sign it off.

This ensures that the users cannot passively go by the entry and finish the TLP without noticing a new defect was recorded.

As these examples show, our automation relies on the users’ input and never the other way around. This approach ensures the eTechLog8 users always actively make decisions without feeling overwhelmed or disengaged.

Finding where to draw the line on automation has been a tricky path. We all have had automation fever too, but our customers can rest assured. The eTechLog8 users are relaxed but in command. They all know exactly what they are doing!